ColumnUltrasonic Sealers 2025/09/25

Asahi industry and the History of Ultrasonic Welders

Asahi industry has been a leading manufacturer of ultrasonic welding machines since the 1980s. With over 40 years of innovation, we have continually refined our products to enhance usability, welding strength, and durability. These decades of experience have culminated in the development of our flagship model: the QP-01 Series ultrasonic welder.

Asahi industry’s ultrasonic welders are a user-friendly and highly durable model that we confidently offer to our customers. Today, Asahi industry holds the top share in Japan’s handheld ultrasonic welder market. Our products are widely adopted in various businesses, supermarkets, shops, and factories.

Moreover, we are expanding internationally. Since 2012, CE-certified models have been available, compliant with European safety standards. Each unit comes equipped with a globally compatible AC adapter that supports voltages from 100 to 240V, allowing the product to be used around the world.

Our ultrasonic welders are used not only for packaging disposable food containers, but also in industrial manufacturing processes. Typical applications include sealing lids of takeout containers at supermarkets, closing blister packs, creating tamper-evident virgin seals, and more. Thanks to their reliability, our devices are trusted in a wide range of settings.

Features of Ultrasonic Welding

Ultrasonic welders—also known as ultrasonic welding machines, ultrasonic sealers, handheld ultrasonic welders, or clamshell sealers.

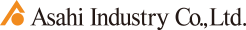

These machines convert electrical energy into mechanical vibration. When combined with pressure, these vibrations generate intense frictional heat at the joint interface of thermoplastics, melting and bonding the materials together.

Because ultrasonic welding melts and solidifies materials instantly, there is no need to wait for adhesives to dry. The process does not require harmful substances, ensuring safety for users.

Also, because there are no auxiliary materials like staples, rubber bands, or tape involved, there’s no risk of foreign matter contaminating the package. Additionally, there is less waste generated, making it an eco-friendly solution.

Compared to heat sealers, ultrasonic welders don’t have hot horns, eliminating the risk of burns. They use vibrations to generate frictional heat inside the resin, enabling faster and stronger bonds even with thick materials.

Key Advantages of Asahi industry’s ultrasonic welders

1. Outstanding Welding power and Work Speed

By simply gripping the handpiece, ultrasonic vibrations at a frequency of 40,000 to 50,000 times per second are emitted from the tip horn. This creates frictional heat between the bonding surfaces, instantly fusing the resin.

No heat, adhesives, tape, or staples are required, making for fast and hygienic bonding. Ideal for a wide range of applications, from food containers and disposable packaging to blister and clamshell packs, and industrial resin processing.

2. Powerful Bonding with Dual Vibration

While most ultrasonic welders use only lateral (horizontal) vibration, Asahi industry’s ultrasonic welders adopt a unique structure that combines both vertical and horizontal vibrations. This delivers stronger bonding performance compared to conventional models.

3. User-Friendly Design and Work Efficiency

The tip of the horn is extended forward, making it easier to clearly see where the welding is happening. This solves a common problem in vertical vibration models where the view is often blocked, and helps ensure accurate work.

Additionally, the handpiece has a compact shape that fits naturally in your hand, so it remains comfortable to use even for long periods without causing strain.

4. Safety Feature: Anti-Empty Activation Function

“Empty activation” occurs when the machine emits ultrasonic vibrations without any material between the horns. This causes the intense vibrations to reflect back into the device, potentially damaging the horn and causing malfunctions.

QP-01 series are equipped with an automatic detection mechanism that stops the vibration when no material is detected. This prevents accidental empty activation during fast-paced operation or if the handpiece is mistakenly gripped without material, protecting the device and extending its lifespan.

*Note: L-QP-01/L-QPB-01 do not include Anti-Empty activation function.

5. Compatible with Global Voltages

All Asahi industry ultrasonic welders come with standard AC adapters compatible with 100–240V. This allows immediate use not only in Japan but also in overseas workplaces. CE-certified models have also been available since 2012, greatly expanding our export and global installation potential.

Applications Across Industries

Asahi industry’s ultrasonic welders are widely used in various fields, including:

Food Industry

- Sealing lids of disposable takeout containers

- Packaging of plastic clamshell containers at supermarkets

- Sealing disposable plastic containers for deli products/li>

- Creating tamper-evident virgin seals

Industrial and Manufacturing Sectors

- Sealing blister and clamshell packaging

- Sealing pouches containing small parts

- Joining nonwoven fabrics and synthetic fibers

Laundry Industry

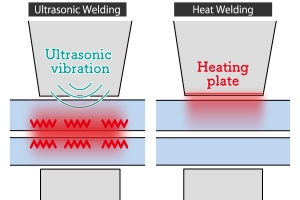

- Joining and bonding ironer guide tapes together

Ultrasonic welders can process thermoplastics such as plastics, synthetic resins, PET, PP, PE, and nonwoven fabrics. It offers strong, fast, and hygienic bonding across various sectors.

Product Lineup

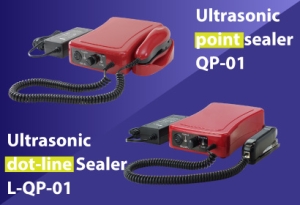

Asahi industry currently offers four ultrasonic welder models: two with power cords and two cordless versions. These models support two welding styles—spot welding, which creates small, precise weld points, and dot-line welding, which forms a series of connected dots for a more continuous seal.

| Model | Type | Features |

|---|---|---|

| QP-01 | Wired | Standard spot-welding model |

| QPB-01 | Cordless | Spot-welding, easy to carry |

| L-QP-01 | Wired | Dot-line welding capability |

| L-QPB-01 | Cordless | Dot-line welding with cordless mobility |

Dot-line welding models also support optional tips for spot welding.

- Spot welding types are frequently used for clamshells and blister packs and in the sealing of ironer guide tapes in commercial laundry operations.

- Dot-line welders are often used for chemical fiber fabrics and nonwoven material welding, making them suitable not only for packaging but also for manufacturing processes.

For more details, please see the related column.

[Column] Differences between Ultrasonic point sealer QP-01 and Ultrasonic dot-line Sealer L-QP-01

https://asahi-sg.co.jp/inquiry/

Free Welding Test Available

Thinking of introducing ultrasonic welding to your operations? We offer free welding tests using your actual samples. Simply send your materials to us, and we will conduct a test and provide the results. We can also return the samples upon request.

Please feel free to contact us for more information.

Contact

https://asahi-sg.co.jp/inquiry/

FAQ

Q. What happens if I accidentally pinch my finger?

A. Don’t worry. Our products are designed with safety in mind. If a finger is caught, the switch will not activate, and no vibration will occur. There is no risk of injury from accidental operation.

Q. Does ultrasonic welding affect the human body?

A. No. There is no harm to the human body. Ultrasonic technology is used in many fields such as medicine and industry. For example, it is used in medical ultrasound devices to examine babies in the womb. It is a highly safe technology.

Q. Can ultrasonic welders bond paper?

A. Standard copy paper cannot be bonded using ultrasonic welding. However, papers with laminated or coated surfaces may be weldable in some cases. Please note that our products are not suitable for binding regular paper as a stapler replacement.

Q. Can I adjust the bonding width?

A. Unfortunately, the bonding width cannot be changed due to the structural limitations of the device. Each model performs welding at a fixed width.

Asahi industry’s Ultrasonic welding machines

[Corded] https://asahi-packaging.com/products/quppa/

[Cordless] https://asahi-packaging.com/products/qpb-01/

Ultrasonic dot-line sealer L-QP-01

[Corded] https://asahi-packaging.com/products/ultrasonic-dot-line-sealer-l-qp-01-for-synthetic-fiber-materials/

[Cordless] https://asahi-packaging.com/products/ultrasonic-dot-line-sealer-l-qp-01-for-ironer-guide-tape-welding-cordless-type/

Contact

We seek new merchandise for the Japanese market. We would like to help you deliver your products to Japanese customers utilizing our broad sales network in Japan. Contact us by email or the contact form below.

Inquiries by phone

| Packaging, Food Sanitation, Food Processing Devices, and Healthcare products

TEL:+81-52-671-5193 |

TEXTILE INDUSTRY-related

TEL:+81-76-423-8154 |

Inquiry by Email