LONG SELLER

Ultrasonic point sealer QP-01

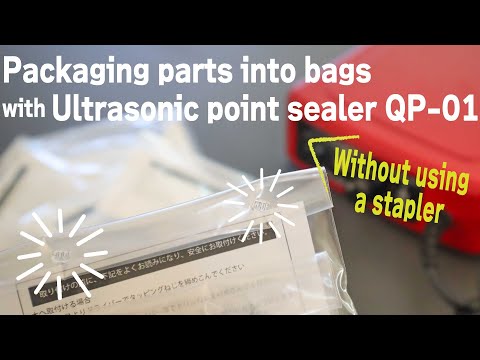

Ultrasonic point sealing of plastic materials without staples

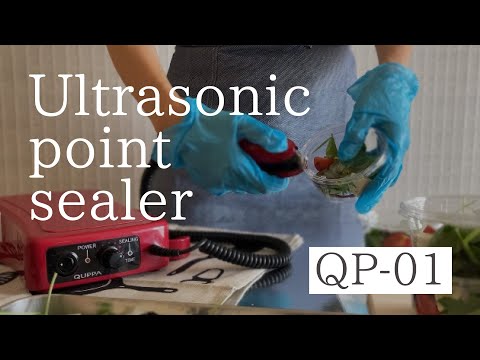

Ultrasonic point sealer QP-01 instantly melts and bonds materials using ultrasonic vibrations emitted from the tip of the handpiece.

By holding the handpiece for just a few seconds, materials can be quickly welded.

Since Ultrasonic welder does not generate heat, it offers a high level of safety.

Ready to use immediately after powering on and features a simple and user-friendly

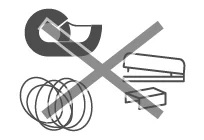

As a cost-effective alternative to tape, adhesives, and staples, Ultrasonic welder requires no consumables.

Key advantages

Tamper-evident seals – Ensures product safety.

No drying time required – Unlike adhesives, bonding is instant.

Easy to operate – Simple and user-friendly design.

Compact and portable for convenient use – Available in both corded and cordless models.

Maintains packaging aesthetics – Discreet and minimal weld marks.

Complies with CE standards

Made in Japan

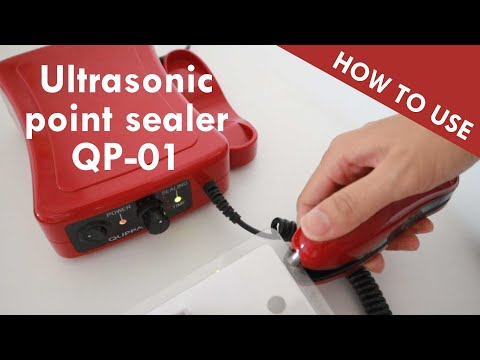

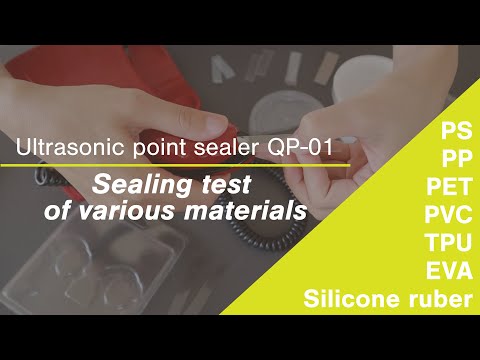

Compatible materials for welding – PP, PET, PVC, PSP, OPS, HIPS, PPF, A-PET and other thermoplastic resins.

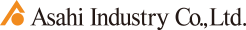

Packaging applications – plastic sheets, non-woven fabrics, pouches, blister packs, clamshells, plastic disposable food containers, ironer guide tapes and so on.

Ultrasonic welder/ Ultrasonic welding machine/ Handheld ultrasonic welder/ Clamshell welder/ Clamshell sealer/ Handheld plastics welder

Download

Usage Examples

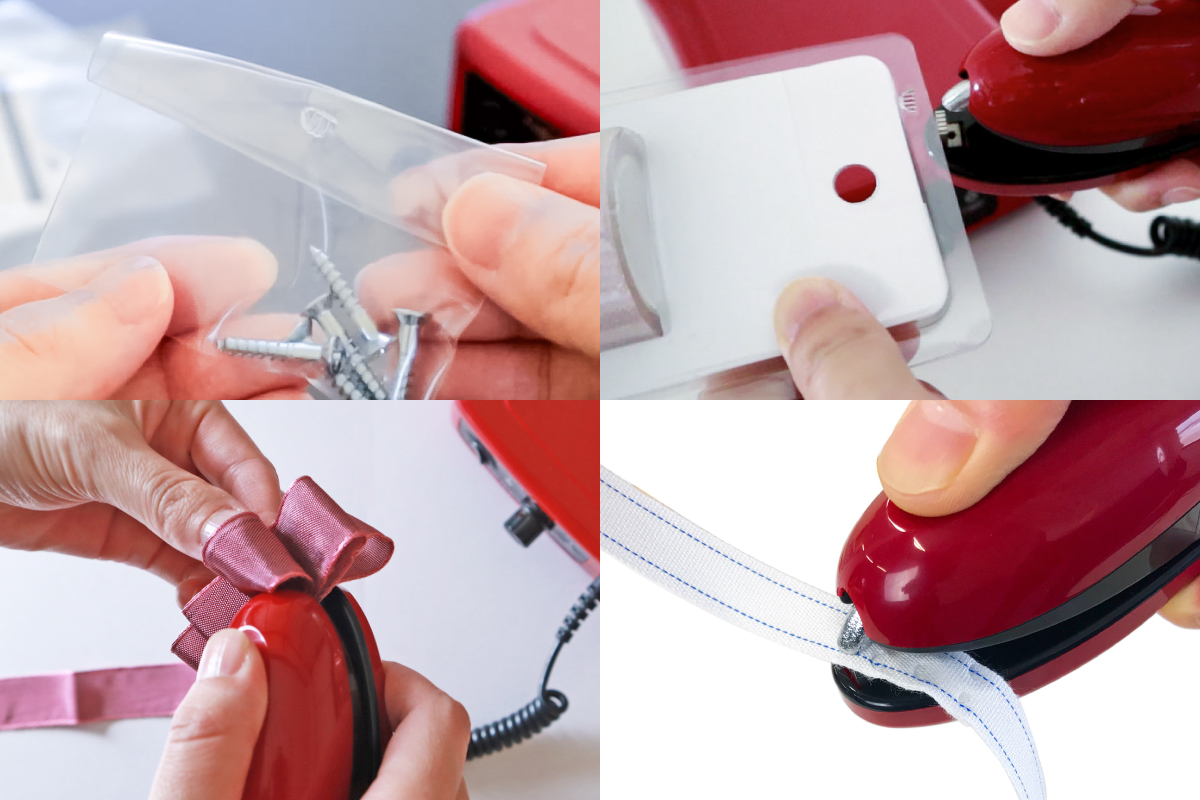

Demonstration Videos

Features

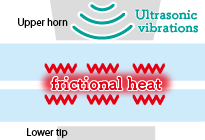

Basic Principles of Ultrasonic Welding

The upper horn of the handpiece vibrates approximately 40,000 to 50,000 times per second.

This vibration is transmitted through the thermoplastic materials to the joint interface, generating frictional heat.

When the temperature at the joint interface reaches the melting point, the plastic melts.

Easy to operate

Simply hold the handpiece for a few seconds to weld the material.

Cost effective

The ultrasonic welder melts and bonds the material itself, eliminating the need for joining materials such as adhesives, tapes, or staples. Since no consumables are required, it is both cost-efficient and eliminates the need for frequent supply management.

Environmentally friendly

Ultrasonic welding operates with just a machine and small amount of electricity. Since no joining materials are required, recycling after disposal is easier.

Human-friendly

The ultrasonic waves of the QP-01 ultrasonic welder have no harmful effects on the human body. Since it does not use chemicals, ultrasonic welding is a safe choice for any manufacturing environment.

Food safety

Consumables such as needles are not used, and therefore, this sealer can prevent foreign matter from entering and provide attractive packing appearance.

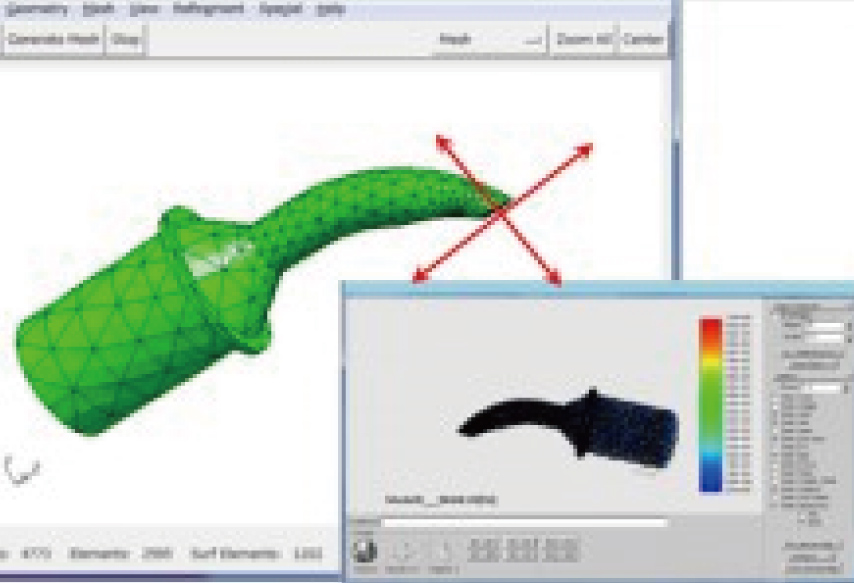

Easy to see contact points

The arc-shaped teeth of the Handpiece allows the user to see the weld points clearly.

Repeated multi-directional vibration

Repeated multi-directional vibration to achieve strong welding.

AC adapter

100V~240V(AC50/60Hz )

It is compatible with voltages worldwide.

Specifications

| Product Name | Ultrasonic point sealer QP-01 |

|---|---|

| Product Number | QP-01 |

| Oscillation frequency | 57kHz |

| Max. output | 20W |

| Max. power consumption | 40VA |

| Power Source | 100V~240V AC 50/60Hz |

| Dimensions / unit | W179×D183×H66mm |

| Dimensions / hand piece | W36×D125×H54mm |

Product Lineup

-

Ultrasonic dot-line sealer L-QP-01

Dotted line sealing by ultrasonic for plastic materials

-

[Cordless] Ultrasonic point sealer QPB-01

For welding food packs, snap-on containers, blister packs, and other thermoplastic materials.

-

Ultrasonic welder AUH30 (100V)

You can easily weld plastic packaging and material by using the various shape of tips. (100V 50/60Hz)

Packaging, Food Sanitation, and Food Processing Devices

We seek new merchandise for the Japanese market. We would like to help you deliver your products to Japanese customers utilizing our broad sales network in Japan. Contact us by email or the contact form below.

Inquiries by phone

| Packaging, Food Sanitation, Food Processing Devices, and Healthcare products

TEL:+81-52-671-5193 |

TEXTILE INDUSTRY-related

TEL:+81-76-423-8154 |

Inquiry by Email