ColumnSealers 2026/01/26

Essential Commercial Sealers for Packaging Baked Goods: A Detailed Guide by Type

When it comes to hygienically and efficiently packaging baked goods and food products, a reliable sealing machine is essential. By securely sealing the opening of the bag, sealers help maintain product quality, preserve appearance, and support proper hygiene control.

However, the term “sealer” encompasses a wide range of machines with various shapes, features, and mechanisms.

In this article, we’ll introduce three of the most commonly used professional-grade sealers found in commercial kitchens, bakeries, and food production sites. We’ll explain their characteristics, price ranges, advantages, and disadvantages in detail.

Whether you’re planning to introduce a sealer for the first time or considering an upgrade, this guide will help you make an informed decision.

1. Most Affordable and Basic: Tabletop Impulse Sealer

The most standard and cost-effective option is the tabletop impulse sealer. It operates by generating heat only while the sealing bar is pressed, allowing for simple and precise sealing of bags.

Key Features

- Sealing is done manually by pressing down the bar while holding the bag in place

- Heat time can be set with a timer

- Widely used for packaging food, components, miscellaneous goods, and more

Advantages

- Very affordable and easy to adopt

- Heats instantly, allowing for quick use after powering on

- Simple design makes it easy to operate and store

Disadvantages

- Requires one hand to press the sealing bar and the other to hold the bag

- Heat levels may fluctuate with prolonged use, requiring adjustments

- Not ideal for sealing heavy or spillable contents

- Repetitive pressing can be physically taxing during long production runs

- Less suitable for large-scale work

Recommended For

- Small-scale production or trial use

- Workspaces with limited installation space

- First-time users who want to try a sealer casually

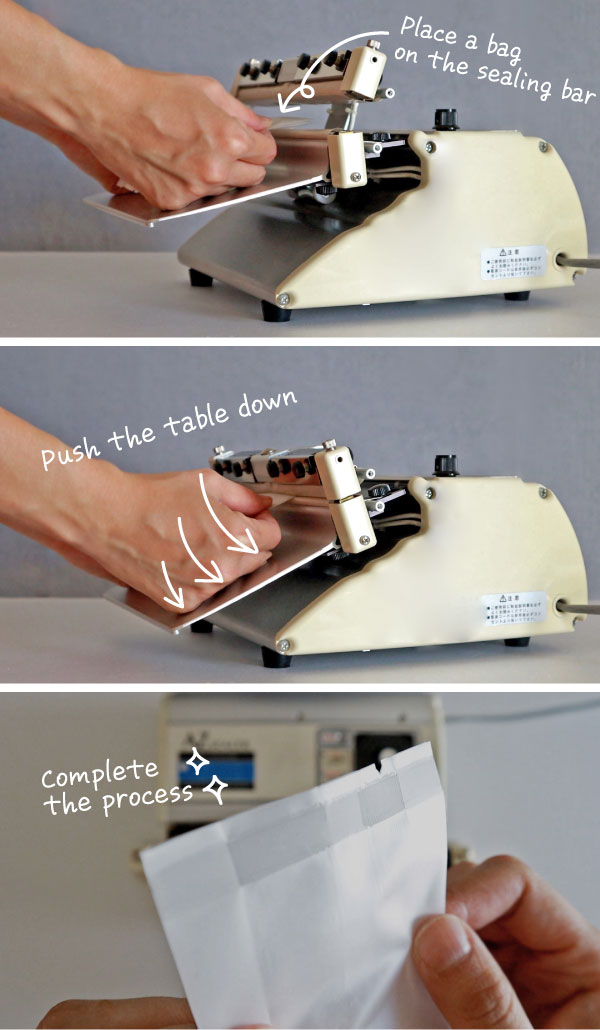

2. Improved Workflow: Tabletop Sealer with Work Table

This sealer uses the same impulse heating method as the basic type but includes an attached table. The major advantage is the ability to use both hands to hold the bag during sealing. Some models also feature foot pedal operation, allowing users to seal without using their hands.

Key Features

- Both hands can be used to support the bag during sealing

- Enables straight, beautiful seals with consistent alignment

- Reduces physical burden on workers

Advantages

- Two-handed operation improves sealing accuracy

- Easy to use for extended periods, with many models requiring less force

- Easy to handle for anyone, with consistent work quality

Disadvantages

- Slightly more expensive than basic tabletop types

- Less suitable for mass production compared to continuous sealers

- May require adjustment due to heat build-up

Recommended For

- Businesses looking to improve packaging efficiency

- Medium-sized operations

- Facilities where sealing tasks are shared among staff

- Brands seeking high-quality packaging finishes

3. Maximum Productivity: Continuous (Endless) Sealer

As the name suggests, continuous sealers are designed for nonstop sealing, using a conveyor belt to automatically feed and seal bags. These machines are ideal for operations that prioritize speed, consistency, and large-scale output.

Key Features

- Bags are automatically fed and sealed by conveyor

- Adjustable sealing temperature and conveyor speed

- Maintains consistent sealing quality

Advantages

- Ideal for high-speed, high-volume production

- Precise control prevents seal variation

- Delivers consistent results regardless of operator skill

- Reduces manual labor burden

Disadvantages

- Higher initial cost

- Larger machine size requires ample space

- Some models require preheating and cooling

Recommended For

- Factories or workshops engaged in mass production

- Businesses seeking labor-saving solutions

- Operators needing fast, high-quality output

Comparison Table

| Type | Key Features | Best For |

|---|---|---|

| Tabletop Impulse

|

Low cost, manual one-hand use | Small-scale, trial applications |

| Tabletop with Table

|

Two-hand operation, high accuracy | Medium-scale, efficiency-focused |

| Continuous Sealer

|

Fast, bulk production | Large-scale, quality & speed-driven |

Frequently Asked Questions (FAQ)

Q1. Can I seal thick bags such as gusseted or multi-layer films?

A. Yes, but some models may struggle with output depending on the bag thickness. For thicker bags, we recommend high-output types like double-heated sealers or continuous sealers.

Q2. What should I keep in mind when using the sealer for food packaging?

A. Choose models that are easy to clean and preferably made of stainless steel. Always wipe the sealing area after each use and maintain hygienic practices.

Q3. What’s the difference between impulse and continuous sealing types?

A. Impulse sealers operate manually one seal at a time, while continuous sealers use a conveyor system to automate the process. Choose continuous sealers for high-volume production and impulse types for occasional or small-batch work.

Q4. Are consumables and maintenance required?

A. Yes. Impulse sealers require periodic replacement of heater wires and Teflon tape. Continuous sealers may need seal belt replacements and internal part checks. Regular maintenance helps prolong machine life and ensures seal quality.

Conclusion

The ideal sealer for your business depends on your production volume, bag type, and the level of finish you require. Take time to review your production style and choose a model that matches your workflow and work environment.

Success lies not just in finding the cheapest machine, but in balancing efficiency, usability, and sealing quality.

We hope this guide helps you find the perfect sealer for your needs!

Related Column

Understanding Heat Sealers: What is a bag sealing machine?

https://asahi-packaging.com/column-heat-sealer/

Recommended Models

AZ-200W or AZ-300W

The double-sided heating sealer is recommended for sealing thick bags, including multi-layer bags such as gusseted bags and fin-seal bags.

https://asahi-sg.co.jp/products/azsealer/

【Contact】

https://asahi-packaging.com/inquiry/

We seek new merchandise for the Japanese market. We would like to help you deliver your products to Japanese customers utilizing our broad sales network in Japan. Contact us by email or the contact form below.

Inquiries by phone

| Packaging, Food Sanitation, Food Processing Devices, and Healthcare products

TEL:+81-52-671-5193 |

TEXTILE INDUSTRY-related

TEL:+81-76-423-8154 |

Inquiry by Email