ColumnSealers 2025/07/25

Understanding Heat Sealers: What is a bag sealing machine?

When you need to seal the opening of a bag, the machine you use is called a heat sealer, sealing machine, bag sealer, or simply a sealer.

These machines vary in performance, particularly in terms of the film thickness they can handle and how they apply heat. Therefore, it’s crucial to carefully consider their features when making your selection.

On this page, we’ll guide you through the characteristics of heat sealers and how to choose the right one for your needs.

What is Heat sealing?

Heat sealing is a processing method that uses heat and pressure to melt materials like plastic films, then cools them to bond and seal. Simply put, it’s a technique that uses heat to join the opening of a bag or two film layers together, without the need for adhesives.

How It Works

The principle behind heat sealing is actually quite simple:

- Melting with Heat: First, a machine called a sealer applies heat to the part you want to seal, such as the opening of a bag. This instantly melts the plastic material at that spot.

- Applying Pressure: While the films are in their melted state, the machine firmly presses them together, applying pressure to ensure close contact.

- Cooling to Solidify: By cooling the melted plastic while maintaining pressure, it solidifies again, joining together as if it were a single piece. This creates a perfect, airtight seal.

Crucial in Our Daily Lives!

Heat sealing is an indispensable technology in our everyday lives:

- Preserving Food Freshness: For snacks, bread, frozen foods, and more, it protects them from air and moisture, extending their deliciousness and freshness.

- Hygiene and Safety: It helps maintain the sterile condition of pharmaceuticals, medical devices, and industrial products, preventing contamination.

- Protecting Quality: Heat sealing also safeguards the quality of moisture-sensitive electronic components and food aromas, keeping their properties intact.

Bag Thickness and Sealer Performance: Are You Choosing the Right Sealer?

Have you ever tried to seal a bag with a sealer and thought, “Huh? It’s not sticking properly…”? The truth is, this might be happening because the bag’s thickness and your sealer’s capability aren’t a good match.

Thin Bags Are Fine for Simple Sealers, But What About Other Types Of Bags?

For everyday, thin plastic bags made of single-layer film, a basic, simple sealer will work just fine. However, there are many bags out there that are much thicker and require a high-performance sealer.

The Key Factors: “Number of Layers” and “Total Thickness”!

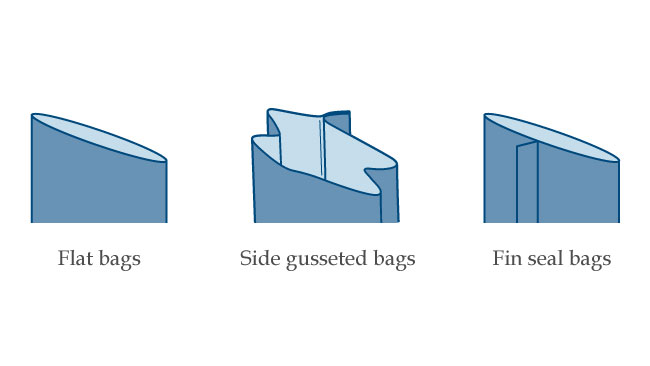

When you’re sealing, it’s not just the thickness of a single film that matters, but how many layers of film your sealer needs to melt and bond together.

- For a flat bag: The film will overlap, resulting in two layers needing to be sealed.

- For a gusseted bag: When you include the side gussets, you could be dealing with as many as four layers!

- For Fin seal bag: Including the fin, the film overlaps in three layers.

The more layers of film that overlap, the more powerful the seal pressure and heating capacity your sealer will need to effectively melt and bond them together.

If you’re having trouble sealing bags with your current sealer, it’s crucial to check the total thickness of your bag (including all overlapping layers). Then, make sure to choose a sealer with the appropriate output for that thickness. To protect the quality of your products, please consider the “thickness” perspective when reconsidering your sealer choice.

The Right Sealing Method: The Key to Success

The most important factor when choosing a sealer is to pick one that matches the shape and thickness of the bags you’ll be using. The amount of heat and pressure required will be entirely different for thin, single-layer film bags versus thick, multi-layered ones.

For example, a gusseted bag with a bottom or side fold will have several layers overlapping at the sealing point, requiring a more powerful sealer. Understanding whether your bag is a flat pouch or a gusseted bag, and how thick it is, is the first step in selecting the right sealer.

Maximizing the Effectiveness of Oxygen Absorbers

If you’re using an oxygen absorber in your bags, it’s crucial to ensure that the bags are completely and tightly sealed without any gaps. Even the most effective oxygen absorber will lose its effectiveness significantly if the seal is not properly made and even the slightest gap is present, as air can enter and compromise the oxygen-removal performance.

If you find gaps in your seal after sealing, try these adjustments:

- Adjusting Time: Slightly increasing the sealing time can ensure the heat transfers properly and creates a secure weld. However, be careful not to make it too long, as this can over-melt or scorch the film. Adjust gradually while observing the results.

- Allow some time for the seal to cool after applying heat: If you release the pressure immediately after heating the melted film, the bond might be weaker. By keeping the pressure applied with the sealer for a little while as it cools, the welded area will set firmly, resulting in a stronger and more beautiful seal.

The Crucial “Cooling Step” in Sealing

Do you think simply applying heat is enough when sealing bags with a sealer? Actually, achieving a beautiful and durable seal hinges on a critical balance between heating and cooling. Let’s explore the key points in these two essential steps.

The Mechanism of Sealing: A Delicate Balance of Heat, Pressure, and Cooling Time

To properly seal film, the process requires applying strong pressure with a sealing bar while simultaneously heating the area to melt it. Following this, it’s crucial to cool it firmly to solidify. This entire sequence creates a robust sealing force.

The Often-Overlooked Importance of “Cooling Time”

Many sealers allow you to set the heating time, but the cooling time is often left to the operator’s discretion. This is precisely where the quality of the finish can differ significantly!

Depending on the bag material and the sealer machine, a good guideline for cooling time is to make it at least double the heating time.

Some people might immediately release the handle once the heating lamp turns off, but this is not recommended. Releasing the sealing bar right after applying heat means the film hasn’t had enough time to cool and solidify. This can lead to a cloudy, wrinkled, or unattractive seal, and more importantly, it can compromise the seal’s integrity.

The Extra Step for a Beautiful Sealing

If you’re aiming for a highly transparent, wrinkle-free, and, most importantly, strong seal, try to keep these points in mind:

- Don’t release the sealing bar immediately after the heating lamp turns off.

- Keep holding the sealing bar for approximately 2 to 3 times even after the heating lamp goes out.

Adding just this “extra step” can help you achieve a beautiful seal that looks like it was done by a professional.

Recommended Models

AZ-200W or AZ-300W

The double-sided heating sealer is recommended for sealing thick bags, including multi-layer bags such as gusseted bags and fin-seal bags.

https://asahi-sg.co.jp/products/azsealer/

【Contact】

https://asahi-packaging.com/inquiry/

We seek new merchandise for the Japanese market. We would like to help you deliver your products to Japanese customers utilizing our broad sales network in Japan. Contact us by email or the contact form below.

Inquiries by phone

| Packaging, Food Sanitation, Food Processing Devices, and Healthcare products

TEL:+81-52-671-5193 |

TEXTILE INDUSTRY-related

TEL:+81-76-423-8154 |

Inquiry by Email